Our global base of customers and business partners, trusts the development of their solutions in plastic injection molding, to the technical capabilities and competences of our commercial and engineering team, which together with our solid project management, have allowed us to guarantee the fulfillment of project schedules and cost targets on all projects that we have jointly tackled with them.

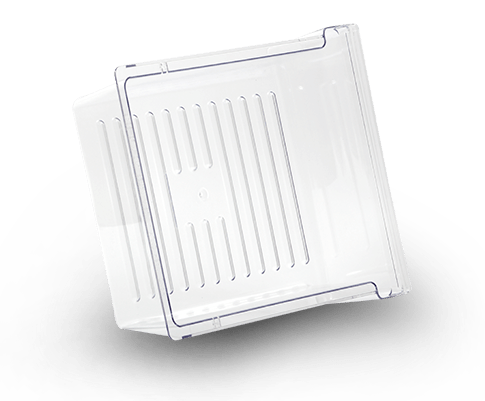

We focus on fulfilling the requirements of the automotive, home appliance and durable goods global industries, through value added parts, components and solutions that meet the highest specifications and technical standards, both aesthetical and functional, through high quality and performance products at competitive costs.

17 Injection Molding Machines y 880 tons, from 5oz./145 grs to 80 oz./1,780 grs