.jpg)

In 2022, Unicar Plastics celebrates its 20 years of success, and has been able to establish a solid reputation in the industry as a reliable, fast, flexible, close and innovative supplier, while building long term relationships with customers, suppliers and associates.

Since its birth, our company has committed itself to an entrepreneurial philosophy that is summarized in our values: customer satisfaction, integrity, commitment to excellence, integral development of the individual, spirit of service and team work, which are the grounds for the development, success and competitiveness that distinguish us from our competitors in the industry.

During this 20 years of efforts, we have obtained the ISO 9001 - IATF 16949 certification, increased the size of our team, and enhanced our production capacity to provide quality parts and components to global brands that bear the highest prestige in the market, and have received the recognition of our customers for our high performance as a supplier in different occasions.

.jpg)

Operations start-up: 2 injection molding machines and 4 associates

First Customers: Apolo Textil and Whirlpool

First Projects Automotive Industry (T2)

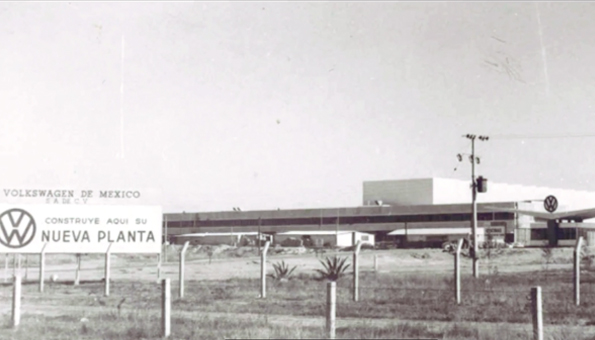

Autoparts Exports to Germany: VW Bora and Golf

Facilities Relocation to San Pablo Xochimehuacan (Expansion Project I)

First Projects Stanley: Ball Pein Hammer Grips

ISO 9001 Certification (Puebla Manufacturing Plant)

Expansion Project II: Quality Lab and FG Warehouse

SAP Business One Implementation

Faurecia and VW approval as T1 supplier

AVX Stanley Export Project: USA/Canada/Europe

VW Jetta A6 and FIAT 500 Production Parts Start-Up

CAD Capabilities: CATIA

10th Anniversary: 25 Injection Molding Machines and 220 associates

2nd Manufacturing Plant in Saltillo, Coahuila with 10 Injection Molding Machines and 65 associates

ISO/TS 16949 Certification (Puebla Manufacturing Plant)

VW Golf A7 Production Parts Start-Up

CIDAUT, Spain R&D Agreeement

First "Mejores Empresas Mexicanas" Award

ISO 9001 Certification (Saltillo Manufacturing Plant)

Corporative Offices in San Andrés Cholula, Puebla

3rd "Mejores Empresas Mexicanas" Award

Endeavor Project (Extension of our Puebla Manufacturing Plant)

4th "Mejores Empresas Mexicanas" Award

.jpg)

Manufacturing process and donation of 35,000 protection masks in collaboration with UPAEP and Moldes y Utillajes S.A. of C.V.

Empresa Socialmente Responsable distintion.

Recognition "Mejores Empresas Mexicanas" for the 8th consecutive year.

New clients: Tesla, Bosch, Stellantis

.jpg)